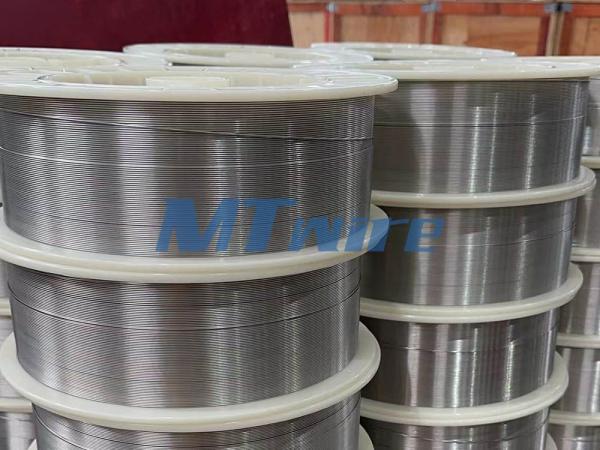

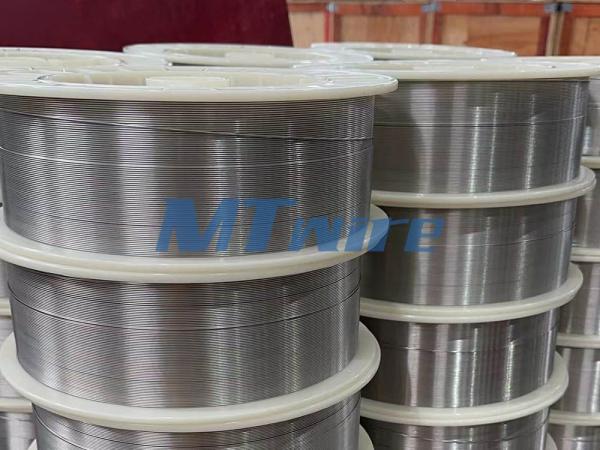

Nickel Alloy Welding Wire

Nickel Alloy Cladding Welding Wire for Power Pipe Overlay Welding

This nickel alloy welding wire is a versatile product designed for a variety of applications including Cladding, Overlay Welding, Hard Surfacing and Build-Up Welding. Superior corrosion, abrasion and high temperature resistance for boiler tubes, water-cooled wall overlay welding, pressure vessels and other applications, enhancing the durability and corrosion resistance of material surfaces. Whether it's restoring surface hardness to tools, machine parts and structural elements, or complex welding and repair tasks on heavy machinery, pressure vessels and large structures, this nickel alloy welding wire is the ideal choice.

Nickel Alloy Cladding Welding Wire for Power Pipe Overlay Welding

| Material | Nickel Alloy Wire |

| Grade | Alloy 600, 601, 625, X-750, 718, C2000, C22, C276, C4, X, 400... |

| Standard | ASTM B166/B446/B637/B574/AME4730 |

| Size | φ0.15mm-φ16mm; Or According To Customers' Requests |

| Type | Round, flat, core, braiding, staple |

| Condition | Annealed and Soft, 1/2 hard, 3/4 hard and full hard |

| Packing | Woven bag, core, wooden reel, etc |

Nickel Alloy Cladding Welding Wire Advantageous Features:

1. Excellent corrosion resistance: Due to the use of a particular nickel alloy composition, it has excellent resistance to acid, alkali, and salt corrosion.

2. High-temperature oxidation resistance: This wire is able to work for a long time in a high-temperature environment without losing its oxidation resistance.

3. Excellent wear resistance: Through the selected alloy composition and advanced surface treatment technology, a robust protective layer is formed on the surface of the wire, providing excellent wear resistance.

4. Good strength and toughness: high tensile strength and good flexibility.

6. Flexible welding process: Compatible with a wide range of welding processes including Cladding, Overlay Welding, Hard surface, and Build-Up Welding, providing greater flexibility for engineers and welders.

Factory advantages:

Nickel Alloy Cladding Welding Wire Application Areas:

1. Water-cooled wall cladding for boiler tubes: effectively prevents corrosion and wear, and extends the service life of the equipment.

2. Pressure vessel cladding: excellent pressure resistance and wear resistance ensure safe and stable operation.

3. Petrochemical equipment welding: High-temperature resistance and corrosion resistance provide reliable protection for the equipment.

4. Marine engineering welding: It can be used for the welding of key components of ships and drilling platforms.

5. Aerospace parts welding: The perfect combination of strength and toughness makes it the ideal welding material for key parts in the aerospace industry.

6. Welding of building structure reinforcement: The high strength and weather resistance of this wire provide extra security for the structure.

7. Welding of food and pharmaceutical equipment: Excellent corrosion resistance allows it to provide hygienic, safe connections in the welding of food and pharmaceutical equipment.

8. Welding in the automotive industry: Used in welding critical parts, such as engines, chassis, etc., it ensures the strength and durability of the components.

Quality Control:

Quality control of raw materials:

Slight changes in the chemical composition and mechanical properties of raw materials will have a significant impact on the properties of finished steel wire. Therefore, the quality of the base bar is one of the key factors in determining the quality of finished steel wire. We will strictly test the raw materials. Only raw materials that pass the test and meet the standards can go to the next process.

|  |

Company Profile:

Quality Control

Why Choose MTSCO?

Factory Complex

Provide you with cost-effective products and professional services.

One stop procurement of wire products

Leave the complexity to Mtsco and the simplicity to you.

After the test of time for 18 years

Whether the products, services, capital and strength, Mtsco is your optimum partner.

Send Inquiry

*Required fields are marked.

English

English Español

Español Русский

Русский عربي

عربي